What Is AOI (Automated Optical Inspection)?

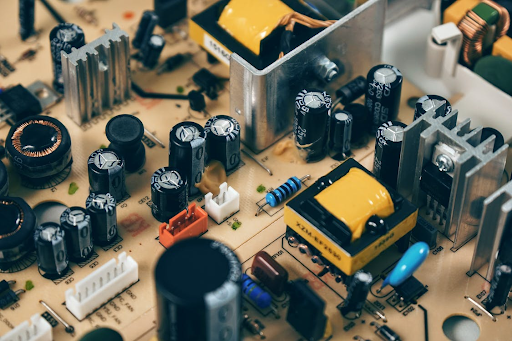

Automated Optical Inspection, generally often called AOI, is a machine-based inspection expertise that permits the detection of defects and flaws in numerous manufacturing processes, together with PCB and electronics manufacturing, automotive, medical, and aerospace industries.

AOI machines, however, use superior pc imaginative and prescient algorithms and various lighting strategies to detect and classify inconsistencies in manufactured merchandise precisely. AOI in PCB Manufacturing is used for the visible inspection of accomplished circuit boards, to detect part alignment, lacking elements, mislabeled elements, and different defects.

Automated optical inspection programs have dramatically reworked the panorama of PCB inspection and are broadly used for high quality assurance functions in fashionable manufacturing services. It entails a machine scanner, a number of mild sources, and cameras, to scan and examine circuit boards utilizing mild imaging.

V1A045 TM Robotic – Case Examine – Continental Automotive Hungary

What Does Automated Optical Inspection Do?

AOI machines make the most of quite a lot of options however we have now right here 10 advantages of utilizing AOI expertise within the PCB manufacturing course of:

- Elevated Accuracy: AOI in PCB makes use of high-resolution cameras and superior algorithms that may detect even the smallest defects or deviations from design specs. It will possibly carry out measurements with micrometer precision, making certain that each one elements and completed merchandise meet the required high quality requirements.

- Value Financial savings: AOI might help producers cut back manufacturing prices by detecting defects early within the manufacturing course of, thus stopping the manufacturing of defective merchandise. This helps keep away from pointless bills akin to materials waste, product recollects, or buyer complaints.

- Improved Productiveness: AOI machines can function at excessive speeds and are able to inspecting 1000’s of items per hour, making it ultimate for high-volume manufacturing environments. This helps producers improve their effectivity and output whereas sustaining the specified high quality requirements.

- Enhanced High quality: With AOI in PCB, producers can confirm the standard of their merchandise earlier than they’re launched to the market. This helps make sure that the merchandise meet their meant efficiency and reliability specs and helps keep the model’s status for high-quality merchandise.

- Elevated Reliability: AOI machines are outfitted with expertise that may determine even essentially the most refined defects, akin to hairline cracks or micro-soldering points, which might compromise the reliability of digital merchandise. It will possibly additionally confirm the integrity of the elements and circuitry, thereby lowering the chance of product failures.

- Quicker Time-to-Market: AOI expertise might help producers speed up their product growth course of by detecting and correcting defects through the manufacturing part, enabling them to launch their merchandise to the market sooner.

- Higher Buyer Satisfaction: Automated optical inspection support producers make sure that their merchandise meet or exceed their clients’ expectations for high quality, reliability, and efficiency. This enhances buyer loyalty and satisfaction, thus strengthening the model’s status out there.

- Compliance with Laws: AOI might help producers adjust to regulatory requirements which require producers to make sure that their merchandise are free from hazardous supplies and meet particular high quality requirements.

- Decreased Downtime: AOI might help cut back downtime brought on by guide inspection processes or tools failures by detecting defects early and alerting operators to handle points earlier than they escalate.

- Improved Security: AOI might help make sure that merchandise are protected to make use of, by detecting defects akin to free connections, soldering defects, or insufficient insulation that may result in electrical shock or hearth hazards.

In essence, automated optical inspection programs supply quite a few benefits to producers, from improved productiveness and value financial savings to enhanced reliability and buyer satisfaction. As expertise continues to advance, AOI programs have gotten extra subtle and able to detecting even essentially the most refined defects. This makes AOI expertise a useful device for producers seeking to enhance their effectivity and high quality assurance processes.

Advantages of Introducing AOI into PCB Manufacturing

The introduction of AOI expertise within the PCB manufacturing course of has revolutionized the {industry}. AOI machines supply a number of benefits over conventional guide inspection strategies, akin to improved accuracy, enhanced reliability, sooner time-to-market, and value financial savings.

The conception and software of AOI in PCB have made the manufacturing course of sooner, extra dependable, and extra environment friendly. And this has translated to value financial savings for producers and elevated satisfaction for his or her purchasers. There isn’t a doubt that AOI expertise is the best way to go for the PCB manufacturing {industry}. Listed here are some extra advantages of introducing AOI into PCB manufacturing:

Larger Manufacturing Effectivity

The introduction of AOI into the PCB manufacturing course of has led to increased manufacturing effectivity. AOI expertise improves manufacturing effectivity by lowering the time wanted to conduct high quality management checks, thereby making it potential to provide PCBs on a 24/7 foundation.

This interprets to elevated manufacturing output, sooner turnaround instances, and decrease manufacturing prices. The machines are designed to function with out relaxation and may carry out an countless variety of inspections with the identical degree of accuracy.

Elevated Inspection High quality

Handbook inspections are susceptible to error, and the diploma of accuracy is restricted by the human eye’s capabilities. AOI expertise, however, gives unmatched accuracy. The machine is designed to examine every PCB meticulously, making certain that no defects are ignored. The expertise can examine small particulars that may be unimaginable for human eyes to detect. Due to a number of optical sensors, AOI programs are in a position to detect even the smallest defects and inaccuracies within the PCBs.

Identification of Defect Patterns

Some of the vital advantages of introducing AOI expertise within the PCB manufacturing course of is its skill to determine defect patterns. The system makes use of subtle software program algorithms to determine patterns within the defects. This data can be utilized to regulate defective processes and make sure that the manufacturing line operates optimally.

By figuring out defects early on within the meeting line, the manufacturing line can constantly enhance, and product high quality will be persistently maintained.

V2A018 TM Robotic – Automated Robotic Optical Inspection (AOI)

Good Software program for a Complete AOI System

Introducing the cutting-edge software program resolution that can revolutionize your manufacturing facility’s AOI operations: TM AI+ AOI Edge. Designed to handle the problem of integrating a number of cameras from disparate workstations right into a centralized management system, our good imaginative and prescient software program harnesses industry-leading applied sciences to streamline and improve your manufacturing facility’s automated optical inspection programs.

On the core of TM AI+ AOI Edge is a strong IPC that may be simply put in in your workstations. By connecting a number of cameras to the IPC, customers can seamlessly function our TMvision capabilities to execute a variety of imaginative and prescient duties, together with object identification, picture enhancement, measurement, and extra.

With TM AI+ AOI Edge, your manufacturing facility’s AOI operations will profit from a number of superior options, together with clever defect classification, adaptive inspection algorithms, and unparalleled scalability that may be simply built-in together with your present manufacturing line.

Moreover, when paired with TM AI+ Coaching Server’s superior analytics and information visualization instruments present real-time insights into your manufacturing line, permitting for sooner, simpler decision-making. Our subtle AI algorithms and machine studying capabilities empower customers to rapidly and precisely determine defects, lowering downtime and bettering total manufacturing effectivity.

Automate with Us!

Techman Robotic’s AI cobots supply a complete resolution for automating your manufacturing facility’s AOI purposes and growing manufacturing effectivity. Whether or not it’s materials dealing with, AOI inspection, or palletizing, these instruments present ease of use and flexibility, making them ultimate for a variety of purposes.

With our software program resolution, you’ll be able to relaxation assured that your AOI purposes are in good arms. Our workforce of consultants is devoted to offering the best degree of buyer assist, making certain that TM AI+ AOI Edge is tailor-made to satisfy the distinctive wants of your enterprise. Contact us as we speak to study extra about how our AI cobots can revolutionize your manufacturing facility’s AOI operations.